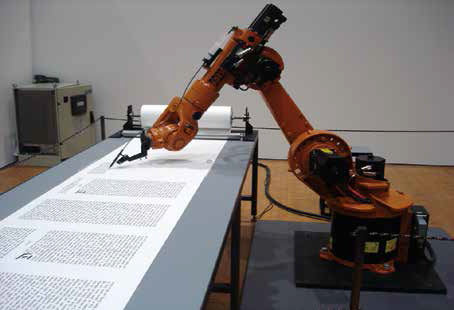

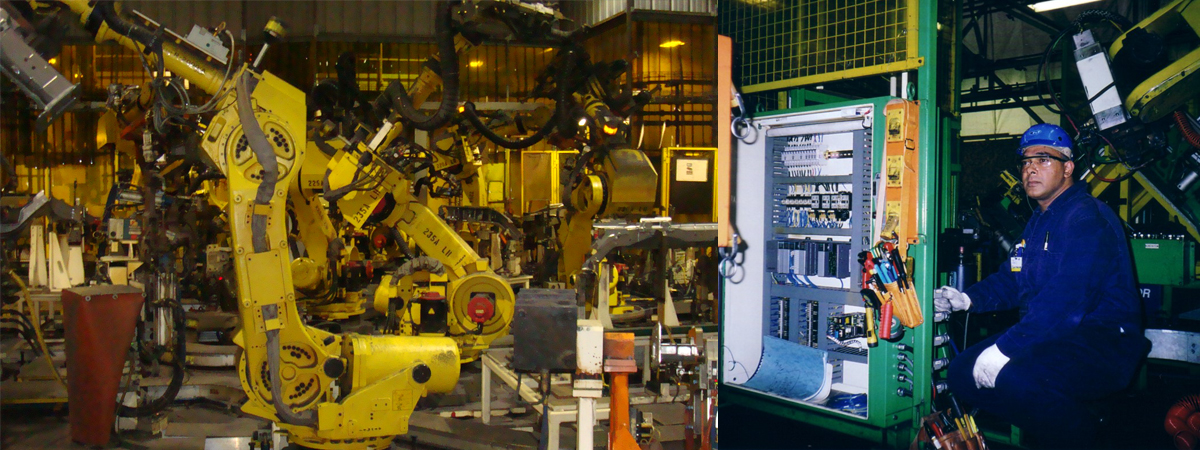

INDUSTRIAL ROBOTIC SYSTEMS

Industrial robotic systems give companies a competitive edge.

Our Services deliver high levels of speed and efficiency, early detection of malfunctions and reduced downtime, regulated quality of product, lower labor costs, and increased productivity.

We offer solutions that are critical and considered high priority in reaching your goals and growing your business.

Preventative Maintenance

- Check alarm history for recurring problems

- Verify DC power supply

- Check mechanical home position

- Check all axis for full range and note any unusual or movement

- Inspect robot for exterior damage

- Check tightness of mounting bolts

- Inspect manipulator cables, timing belts internal wire harnesses and link arm for damage or looseness

- Check all exposed wire to motors, encoders and balancers for damage

- Lubricate all axis speed reducers and any bearing where applicable as per manufactures specifications

- Remove cooling fans (air-conditioning unit) Inspect and clean

- Check controller door for damage. Check seals

- Check all connectors inside of controller for Damage or looseness

- Inspect teach pendant and teach pendant cable for damage

- Blow out controller with air pressure

- Clean robot, controller, teach pendant and Robot area

- Run robot through full range of motion to verify proper function

- Inspect wrist clutch for looseness and function

- Check operation of over travel limit switches

- Verify operation of all E-stops and hold push buttons

- Check all batteries

Services

• Preventative Maintenance

• 24 Hour Emergency Service

• Troubleshooting

• Installation, customization, modification, service, and programming of robots.

• Customization of all industrial machine applications.

• Cost effective Design and Integration of new Robotic systems.

• Complete support programs

Loading Translator ...

Loading Translator ...